Course Description

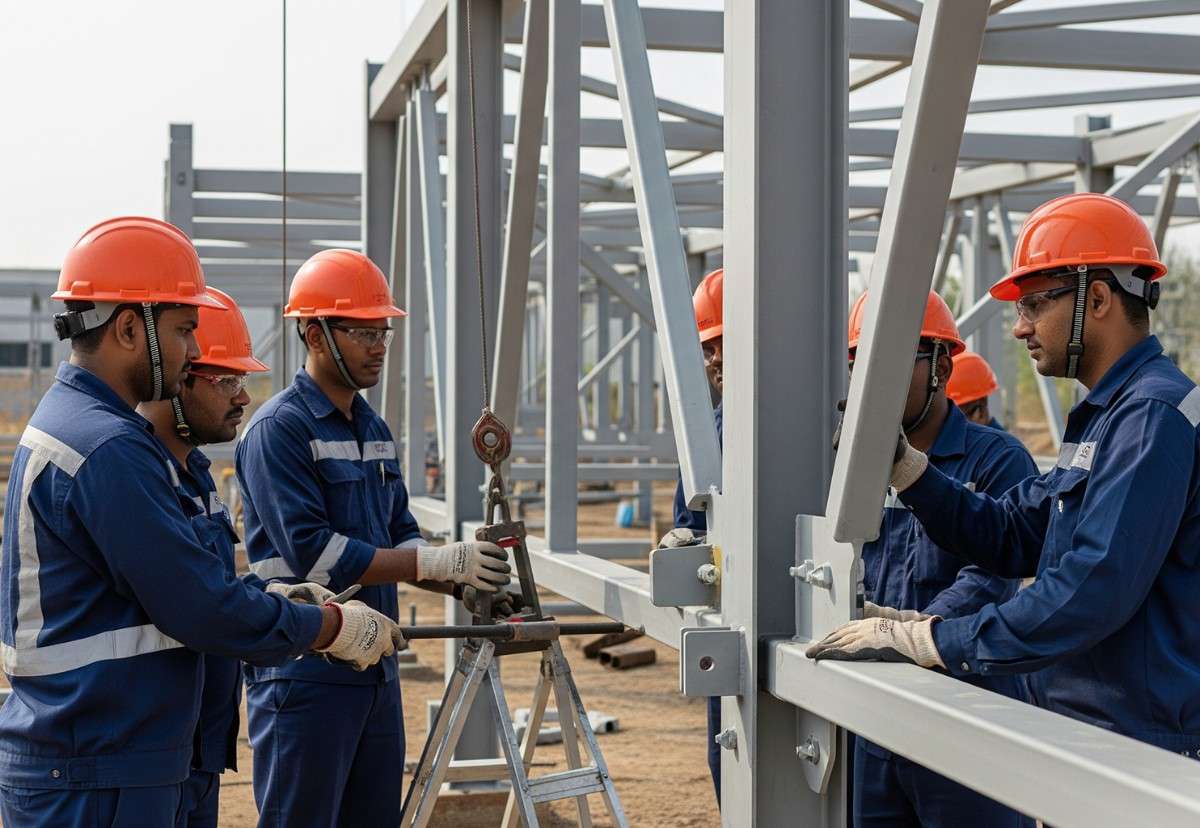

This course focuses on ensuring the integrity of bolted joints in industrial equipment. You will learn proficient English speaking to communicate technical details effectively. Participants will master joint assembly, torqueing, tensioning, and inspection techniques, ensuring leak-free operations.

What you'll learn in this Course?

The Joint Integrity Management Technician program is a specialized, industry-focused training designed to develop strong technical competence in managing bolted joints across EPC, oil and gas, pipeline, and refinery operations. The program covers joint integrity fundamentals, flange management, gasket and seal technology, bolting techniques, inspection, and testing to ensure leak-free and safe operations. Emphasis is placed on compliance with international standards such as ASME and API, safe bolting practices, and proper documentation and audit readiness. Participants gain practical understanding of advanced bolting methods, joint troubleshooting, failure analysis, and preventive measures. By completing the program, learners are equipped to maintain joint integrity, minimize leakage risks, enhance operational safety, and support reliable plant and pipeline performance.

The module highlights how thoughtful planning can directly improve project

quality, reduce accidents, and help projects finish on time and within

budget.

Course Content

-

Joint Integrity Basics

-

Bolting Techniques

-

Inspection and Testing

-

Safety in Joint Integrity

-

Joint Integrity Standards

-

Audit preparation

-

Installation techniques

-

Preventive measures

-

Field vs. shop joint work

-

Bolt elongation checks

Eligibilty Criteria

12th with 2 years experience

Course Benefits

1. Awareness about roles & responsibilities

2. How to use the latest tools, systems and ppe

3. Communication and Interpretation skills

4. How to plan and carry out the task effectively

5. Theoritical knowledge about the subject

6. Latest industry trends and benchmarks

7. Productivity techniques

8. How to approach work safety effectively

Gain proficient English speaking skills, master joint integrity techniques, ensure leak-free operations, and enhance safety and reliability in industrial settings.